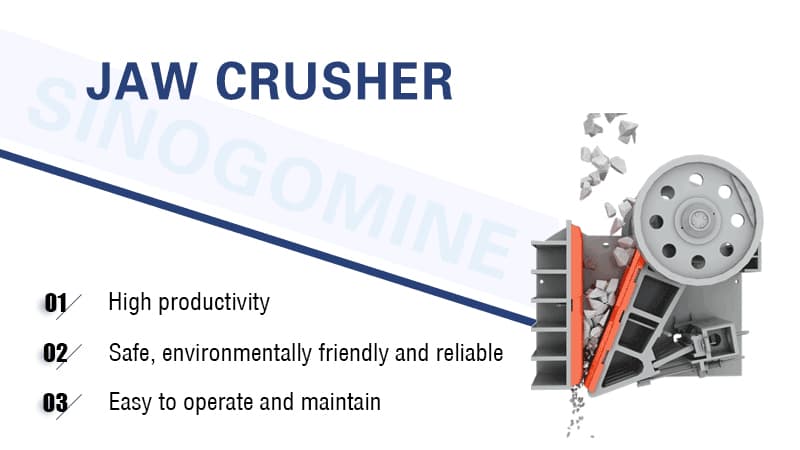

1. Jaw Crusher Application :

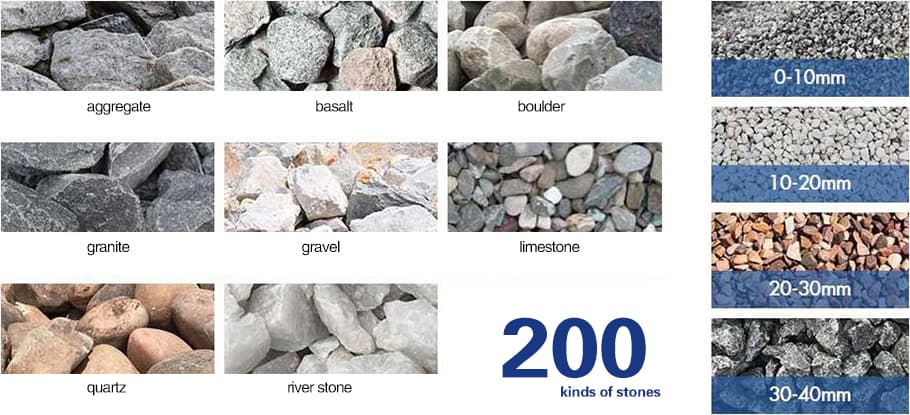

Jaw Crusher Applied materials: limestone, pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, coal gangue, construction waste, ferrosilicon, basalt, sandstone, rocks, ore, glass, cement clinker and some metal.

Jaw crusher Application field is kind of coarse crusher, mainly used in mining, building materials, infrastructure construction etc. It can crush various materials with compressive strength not exceeding 320MPa.

2. Working Principle of Jaw Crusher :

When a jaw crusher works, the motor starts the belt wheel to drive the centrifugal shaft to rotate. The movable jaw blade suspension shaft gets to and away the fixed shaft periodically, which causes a press, rubbing and grinding, etc. to the raw materials. Crushed stone falls down gradually and are discharged out of the jaw crusher when the particle size meets the requirements.

3. All Kinds of Jaw Crusher:

As ideal primary or secondary crusher equipment, jaw crushers with different types are often used in various industries. Depending on different ways of moving or engine, jaw crushers are divided into four types: PE/PEX Motor jaw crusher, Diesel jaw crusher, and Mobile jaw crusher.

-

(Motor Power Jaw Crusher)

(Motor Power Jaw Crusher) -

(Diesel Power Jaw Crusher >>)

(Diesel Power Jaw Crusher >>)

Mobile crushing solutions are also available! You just need to tell our engineer your demand, and we will equip you the right mobile crushers with low energy consumption, low cost, and high efficiency.

Video of Jaw Crusher:

Advantage

-

① Deep crushing cavity which improves capacity.

-

② High crushing ratio and uniform finished production size.

-

③ Single jaw crusher can save power 15% - 30%.

Technical Data

|

Model |

Feed openi ng (mm) |

Max. Feedi ng size(mm) |

Outpu t size(mm) |

Capacity (t/h) |

Power (kw) |

Weight (t) |

Overal Dimensi on (mm) |

|

PE-250X400 |

250X400 |

200 |

20-50 |

5-20 |

15 |

3 |

1430X1310X1340 |

|

PEX-250X750 |

250X750 |

210 |

25-60 |

15-30 |

22-30 |

5 |

1667X1545X1020 |

|

PEX-250X1000 |

250X1000 |

210 |

25-60 |

15-50 |

30-37 |

7 |

1695X1921X1440 |

|

PEX-250X1200 |

1200X250 |

210 |

25-60 |

20-60 |

37-45 |

8.5 |

2192X1900X1950 |

|

PEX-300X1300 |

300X1300 |

250 |

20-90 |

30-90 |

55-75 |

11.5 |

1750X2320X1724 |

|

PE-400 x 600 |

400X600 |

350 |

40-100 |

15-60 |

30-37 |

7 |

1700X1732X1653 |

|

PE-500 x 750 |

500X750 |

425 |

50-100 |

40-110 |

45-55 |

12 |

1950X1878X1855 |

|

PE-600 X 900 |

600X900 |

480 |

65-160 |

90-180 |

55-75 |

19 |

2200X2008X2302 |

|

PE-750 X1060 |

750 X1060 |

630 |

80-140 |

110-320 |

90-110 |

29 |

2624X2302X3110 |

|

PE-900 X1200 |

900X1200 |

750 |

95-180 |

220-450 |

132 |

58 |

3550X2823X3196 |

|

PE-1000 X1200 |

1000X1200 |

850 |

95-190 |

230-500 |

132 |

69 |

3800X3166X3045 |

|

PE-1200 X1500 |

1200X1500 |

1020 |

150-300 |

400-800 |

220 |

100.9 |

4930X3148X3703 |

|

PE-1500 X1800 |

1500X1800 |

1200 |

220-350 |

450-1000 |

355 |

132 |

5630X3210X4120 |

Related Projects

Sinogomine factory is the one with almost 20 years of manufacturing experience in manufacturing crushing machinery the total factory area reached 230000 square meters of which the workshop area was 112000 square meters our main products are stone crushers and briquette press machines.

-

( Customers Vistor ) -

( Customers Vistor )

Quick Way To Get Price And Support

Email: [email protected]

Please feel free to fill in the following form or send us an email, Provide customized solution according to your specific needs.

(Due to the different capacity and transportation costs of various equipment, the final price of the equipment will vary..)

Send Email

Send Email Get Price List

Get Price List