1. Ball Mill Application :

Ball mill is the key equipment for secondary grinding after crushing. And it is suitable for grinding all kinds of ores and other materials, no matter wet grinding or dry grinding. Besides, it is mainly applied in many industries, such as ferrous&non-ferrous metal mine, building materials, chemical, electric power, coal, traffic, light industry, etc.According to different discharging ways, it can be divided into two kinds, grate type and overflow type.

Ball Mill is used to process gold stone, gold rock, gold ores in gold mining industry also.

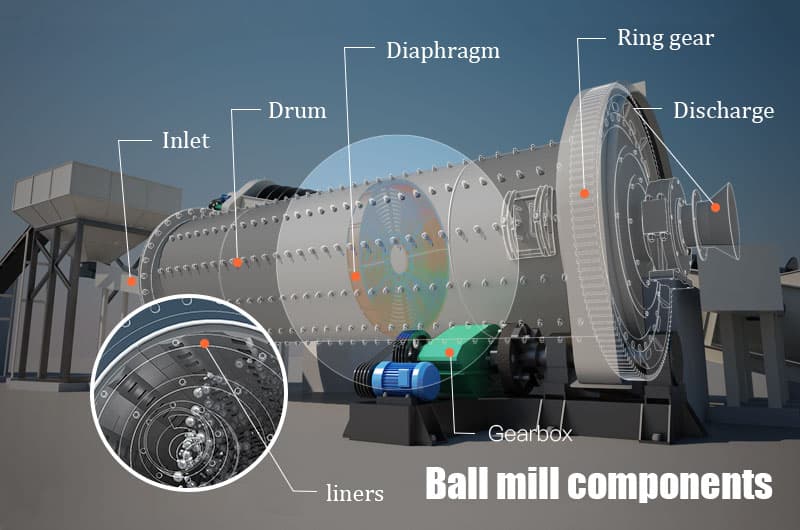

2. Ball Mill Components:

Ball mills consist of the following components:Inlet, Discharge, Drum, Ring Gear, Electric Motor, Gearbox, Bearings

3. Ball Mill Working Principle:

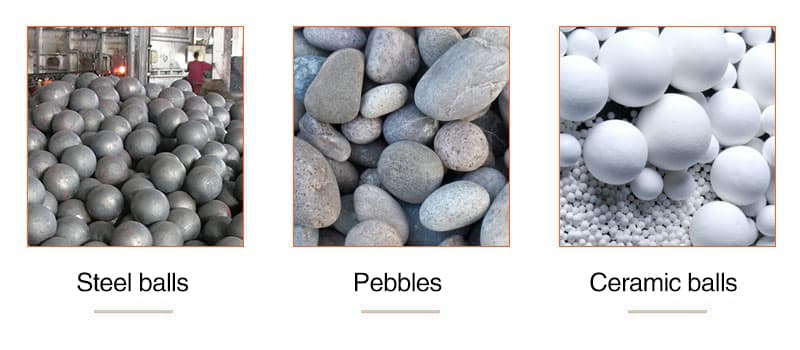

Add balls into the ball drum to approximately 33%. As the ball mill rotates, the balls 'stick' to the inner surface of the ball drum due to the centrifugal force and are lifted on the rising side. At a certain angle, balls cascade down to the centerline of the ball mill because gravity overcomes the centrifugal force. And the ore is reduced to the required size by impact (balls impacting with the ore) and attrition (ore rubbing against other bits of ore and the milling balls).

(Working Principle)

Video of Ball mill:

Advantage

-

High-efficiency.

-

Save energy.

-

Good qualitylong-run working.

Technical Data

| Model | Rotary Speed (r/min) | Ball Weight (t) | Feeding Size (mm) | Output Size (mm) | Capacity (t/h) | Power (kw) | Weight(t) |

| Φ900X3000 | 35.6 | 2.4 | W25 | 0.075〜0.89 | 0.8-2.5 | 22 | 5.3 |

| Φ1200X3000 | 32.4 | 4.5 | W25 | 0.074-0.4 | 1.6-3 | 37 | 12.1 |

| Φ1200X4500 | 32.4 | 7 | <25 | 0.074-0.4 | 1.83-3.9 | 55 | 13.1 |

| Φ1500X3000 | 29.7 | 7.5 | W25 | 0.074-0.4 | 2.8-4 | 75 | 14.8 |

| Φ1500X4500 | 29.7 | 11 | W25 | 0.074-0.4 | 4.8-7 | 110 | 19.9 |

| Φ1500X5700 | 29.7 | 14 | W25 | 0.074-0.4 | 5-8 | 130 | 23.4 |

| Φ1500X7000 | 29.7 | 17 | W25 | 0.07494 | 6-8 | 155 | 27.5 |

| Φ1830X3000 | 25.4 | 11 | W25 | 0.074-0.4 | 4.5-10.5 | 130 | 26.6 |

| Φ1830X4500 | 25.4 | 17 | M25 | 0.074-0.4 | 6.841.5 | 155 | 30.4 |

| Φ1830X6400 | 25.4 | 24 | <25 | 0.074-0.4 | 7-12 | 210 | 32.3 |

| Φ1830X7000 | 25.4 | 26 | <25 | 0.074-0.4 | 7.8-13.8 | 245 | 34.2 |

| Φ2100X3000 | 24.9 | 15 | W25 | 0.074-0.4 | 5.8-14 | 210 | 32.3 |

| Φ2100X4500 | 24.9 | 23 | W25 | 0.074-0.4 | 9.5-18 | 245 | 40 |

| Φ2400 X 3000 | 20.8 | 20 | W25 | 0.074-0.4 | 7.8-18 | 245 | 51.3 |

| Φ2400X4500 | 20.8 | 30 | W25 | 0.074-0.4 | 13.7-28 | 380 | 63.7 |

| Φ2700X4000 | 19.5 | 34 | W25 | 0.074-0.4 | 15-28 | 475 | 89 |

| Φ2700X4500 | 19.5 | 39 | W25 | 0.074-0.4 | 16.5-36 | 475 | 97 |

Related Projects

Sinogomine factory is the one with almost 20 years of manufacturing experience in manufacturing crushing machinery the total factory area reached 230000 square meters of which the workshop area was 112000 square meters our main products are stone crushers and briquette press machines.

-

( Customers Vistor ) -

( Customers Vistor )

Quick Way To Get Price And Support

Email: [email protected]

Please feel free to fill in the following form or send us an email, Provide customized solution according to your specific needs.

(Due to the different capacity and transportation costs of various equipment, the final price of the equipment will vary..)

Send Email

Send Email Get Price List

Get Price List