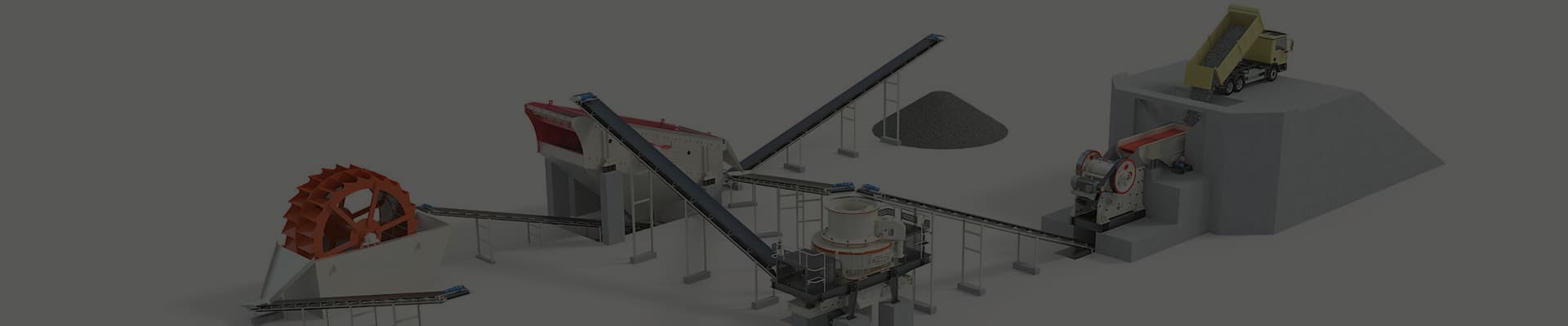

Stone Crushing Plant

How set up stone crusher plant?

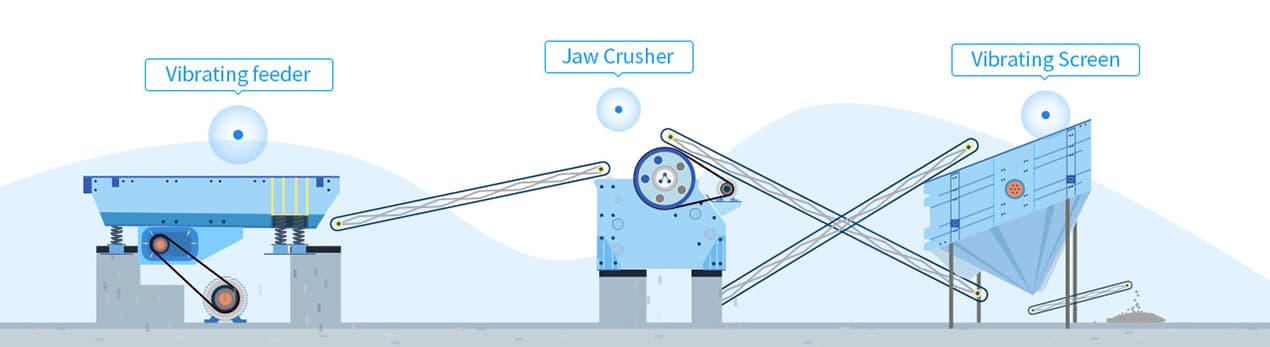

Mini (5 TPH) stone crusher plant

-

-

Raw material hardness

Soft

Feeding size

≦200 mm

Type of production line

Fixed

Floor area

About 50*5 m

Types of finished products

1

-

Capacity: 5 TPH

-

Raw material: Limestone

-

Finished product specifications:0-24 mm

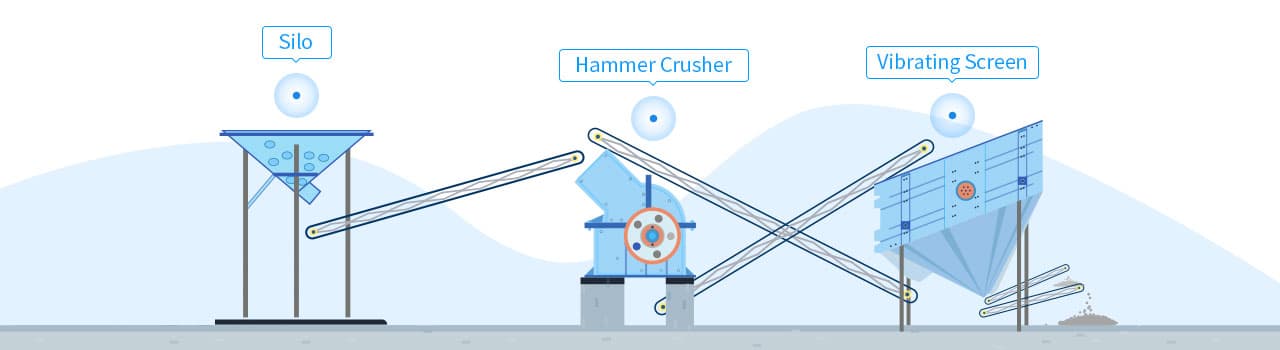

20 TPH stone crusher plant

-

-

Raw material hardness

Soft

Feeding size

≦200 mm

Type of production line

Fixed

Types of finished products

2

-

Capacity: 20 TPH

-

Raw material: Bluestone

-

Finished product specifications:0-10, 10-20 mm

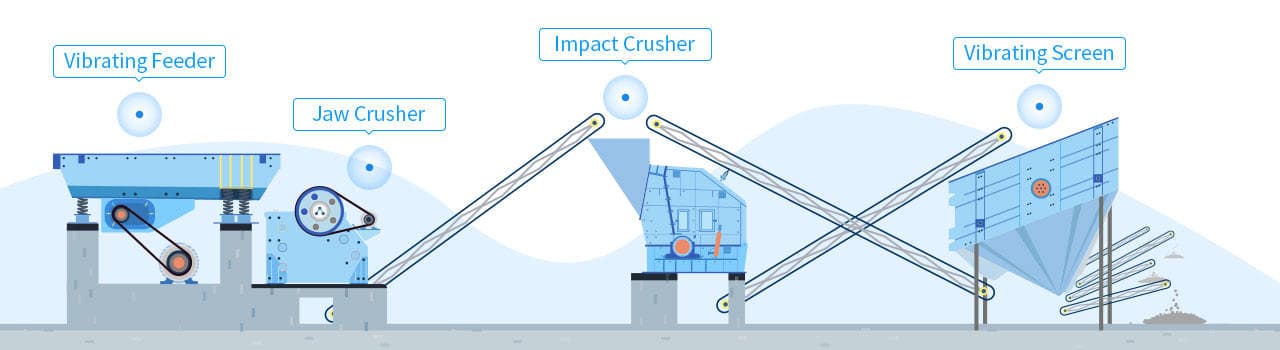

50 TPH-80 TPH stone crusher plant

-

-

Raw material hardness

Hard

Feeding size

≦400 mm

Type of production line

Fixed

Types of finished products

3

-

Capacity: 50 - 80 TPH

-

Raw material: Ore

-

Finished product specifications:0-5, 5-40, 40-70 mm

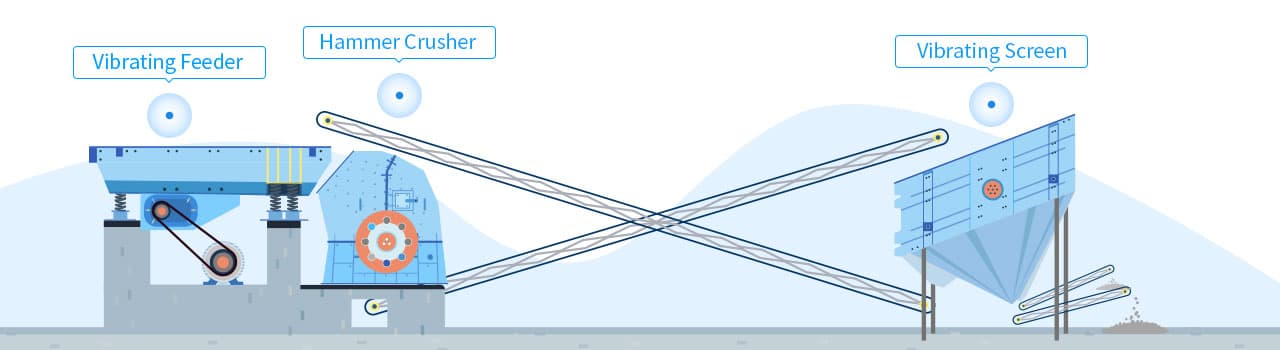

100TPH stone crusher plant

-

-

Raw material hardness

Soft

Feeding size

≦600 mm

Type of production line

Fixed

Types of finished products

2

-

Capacity: 10 TPH

-

Raw material: Limestone

-

Finished product specifications:0-5, 5-10 mm

150 TPH stone crusher plant

-

-

Raw material hardness

Hard

Feeding size

≦500 mm

Type of production line

Portable

Types of finished products

3

-

Capacity: 150 TPH

-

Raw material: Granite

-

Finished product specifications:0-10, 10-20, 20-30 mm

200 TPH stone crusher plant

-

-

Raw material hardness

Hard

Feeding size

≦630 mm

Type of production line

Fixed

Types of finished products

4

-

Capacity: 20 TPH

-

Raw material: Granite

-

Finished product specifications:0-5, 5-10, 10-20, 20-30 mm

300 TPH stone crusher plant

-

-

Raw material hardness

Soft

Feeding size

≦630 mm

Type of production line

Fixed

Types of finished products

3

-

Capacity: 300 TPH

-

Raw material: Limestone

-

Finished product specifications:

600 TPH stone crusher plant

-

-

Raw material hardness

Soft

Feeding size

≦1000 mm

Type of production line

Fixed

Types of finished products

4

-

Capacity: 600 TPH

-

Raw material: Granite

-

Finished product specifications:0-5, 5-10, 10-20, 20-30 mm

Related Machines

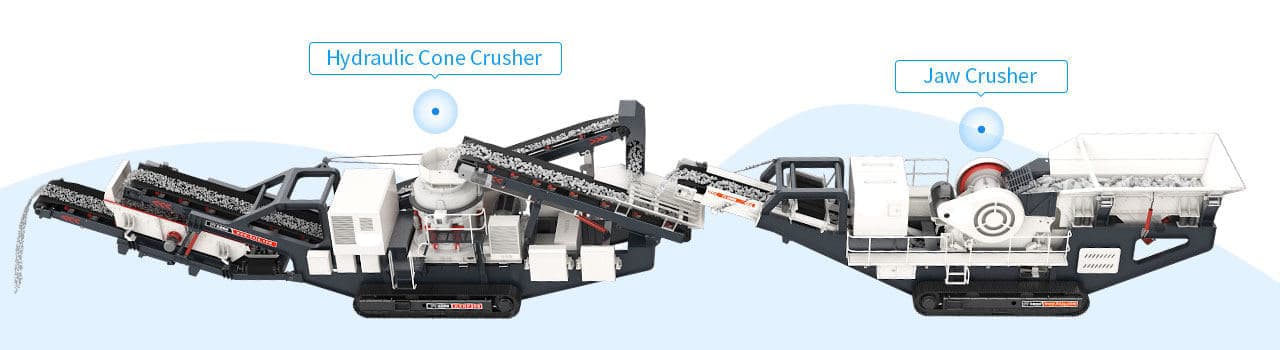

Solution 2:Mobile solution

Mobile crushing solutions are also available! You just need to tell our engineer your demand, and we will equip you the right mobile crushers with low energy consumption, low cost, and high efficiency.

Gomine mobile crushing plant has exclusive benefits you cannot resist:

1. Easy access to constantly moving working environment

2. Shorter transportation time and lower installation cost

3. Versatile body combining alternative equipment, meet customers personalized needs

4. World-class quality, cutting-edge technology, Chinese price

5. Globalization customer site service 6. Easy to resale and higher resale value

Quick Way To Get Price

Please tell us your materials, capacity, You can get the price list and we will contact you asap, you can conctact us by email also.

(

(  (

(  (

(  (

(  (

(  Send Email

Send Email Get Price List

Get Price List